Sehlopha se Phahameng ka ho Fetisisa sa PLA Plastic Food Box Container Thermoforming Machine

Re lumela ho: Boqapi ke moea le moea oa rona. Boemo bo holimo ke bophelo ba rona. Moreki o tla hloka ke Molimo oa rona bakeng sa Sets'oants'o sa Lebokose la Lijo tsa Plastiki tsa PLA tse Phahameng ka ho FetisisaMochine oa Thermoforming, Re amohela ka tieo bareki ba tsoang linaheng tse ling ho buisana le tšebelisano ea nako e telele hammoho le tsoelo-pele e kopanetsoeng.

Re lumela ho: Boqapi ke moea le moea oa rona. Boemo bo holimo ke bophelo ba rona. Moreki tla hloka ke Molimo oa rōna bakeng saMochini oa ho etsa lijana tse lahliloeng,Mochini oa Lebokose la Lijana tsa polasetiki,Mochini oa ho Etsa Lits'oants'o tsa Plastiki,Mochini oa Thermoforming oa Plate,Mochine oa Thermoforming,Terene Formers Thepa , Re molekane oa hau ea ka tšeptjoang limmarakeng tsa machaba tse nang le lihlahisoa tsa boleng bo botle ka ho fetisisa. Melemo ea rona ke boiqapelo, ho tenyetseha le ho ts'epahala tse ahiloeng lilemong tse mashome a mabeli tse fetileng. Re tsepamisitse maikutlo ho faneng ka litšebeletso ho bareki ba rona e le ntho ea bohlokoa ho matlafatsa likamano tsa rona tsa nako e telele. Ho ba teng ha rona khafetsa ha lihlahisoa tsa boemo bo holimo hammoho le tšebeletso ea rona e ntle ea pele ho thekiso le ka mor'a thekiso ho netefatsa tlholisano e matla 'marakeng o ntseng o eketseha oa lefatše.

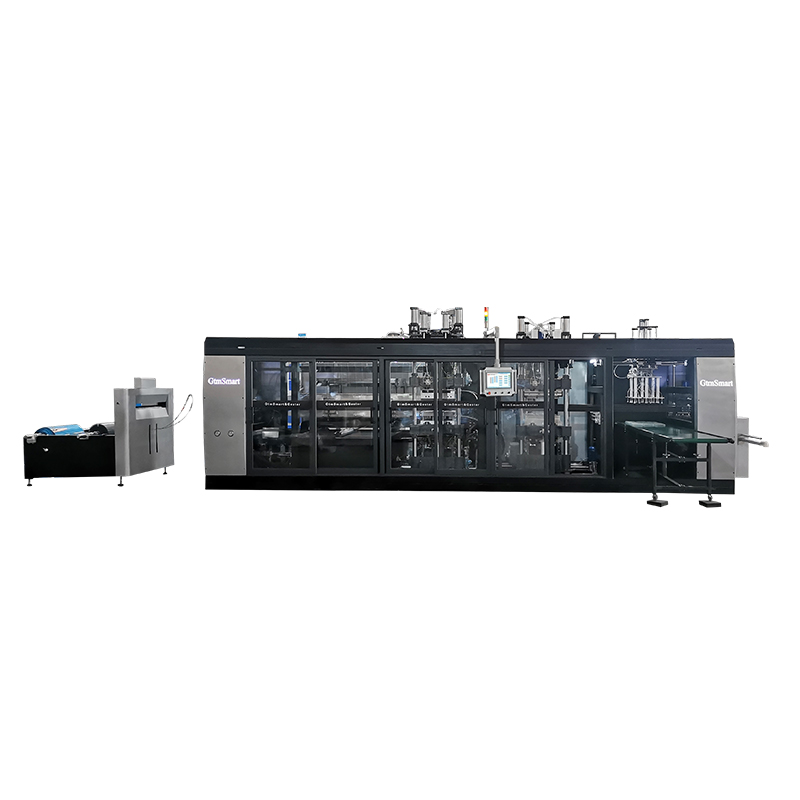

PLAMochine oa Thermoforming

Tlhaloso ea Mochini oa Thermoforming

| Mohlala | HEY01-6040 | HEY01-7860 |

| Sebaka sa Sebopeho sa Max2) | 600×400 | 780×600 |

| Seteishene sa Mosebetsi | Ho theha, ho khaola, ho bokella | |

| Boitsebiso bo sebetsang | PS, PET, HIP, PP, PLA, joalo-joalo | |

| Bophara ba Leqephe (mm) | 350-810 | |

| Botenya ba Leqephe (mm) | 0.2-1.5 | |

| Max. Dia. Ea Sheet Roll (mm) | 800 | |

| Ho etsa Mold Stroke(mm) | 120 bakeng sa hlobo ea holimo le tlase | |

| Tšebeliso ea Matla | 60-70KW/H | |

| Max. Botebo bo Feliloeng (mm) | 100 | |

| Ho Seha Mold Stroke(mm) | 120 bakeng sa hlobo ea holimo le tlase | |

| Max. Sebaka sa ho Seha (mm2) | 600×400 | 780×600 |

| Max. Mold Closing Force (T) | 50 | |

| Lebelo (potoloho/mots) | Boholo ba 30 | |

| Max. Bokhoni ba Pompo ea Vacuum | 200 m³/h | |

| Mokhoa oa ho Pholisa | Pholiso ea Metsi | |

| Phepelo ea motlakase | 380V 50Hz 3 phase 4 terata | |

| Max. Matla a ho futhumatsa (kw) | 140 | |

| Max. Matla a Mochini Oohle (kw) | 160 | |

| Boholo ba Mochini(mm) | 9000*2200*2690 | |

| Leqephe la Carrier Dimension(mm) | 2100*1800*1550 | |

| Weight of Whole Machine (T) | 12.5 | |

Kenyelletso ea Sehlahisoa

SenaMochine oa ThermoformingBoitsebiso bo loketseng:PLA, PP, PS, PET ect.

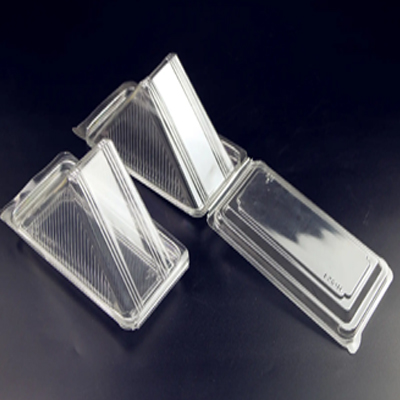

Mofuta oa sehlahisoa: tse fapa-fapanengsenyehangmabokose a polasetiki, lijana, likotlolo, likoahelo, lijana, literei, meriana le lihlahisoa tse ling tsa liphutheloana tsa blister.

Sebopeho

- Motsoako oa mechine, oa pneumatic le oa motlakase, liketso tsohle tse sebetsang li laoloa ke PLC. Sesepa sa ho ama se etsa hore ts'ebetso e be bonolo hape e be bonolo.

- Khatello Le/Kapa Ho theha Vacuum.

- Mochine oa Thermoforming: Ho theha hlobo ea holimo le tlase.

- Servo motor feeding, bolelele ba phepelo bo ka fetoloa hanyane ka hanyane. Lebelo le phahameng le le nepahetseng.

- Hitara e kaholimo le e tlase, likarolo tse nne tsa ho futhumatsa.

- Heater e nang le sistimi ea taolo ea mocheso e phahameng, e nang le ts'ebetso e nepahetseng haholo, mocheso o ts'oanang, e ke ke ea sebelisoa ke motlakase oa kantle. Tšebeliso e tlase ea matla (e bolokang matla a 15%), e netefatsa bophelo bo bolelele ba ts'ebeletso ea sebōpi sa ho futhumatsa.

- Ho theha le ho seha hlobo ea yuniti e bulehile ebile e koalehile e laoloang ke servo motor, lihlahisoa li bala ka bohona.

- Lihlahisoa li behoa ka tlaase.

- Mochini oa Thermoforming oa polasetiki: mosebetsi oa ho hopola lintlha.

- Bophara ba ho fepa bo ka fetoloa ka mokhoa o ts'oanang kapa ka boikemelo ka tsela ea motlakase.

- Heater e tla sutumelletsa kantle ha lakane e felile.

- Auto roll sheet loading, fokotsa mosebetsi o boima.

Letšoao la Likarolo Tse Ka sehloohong

| PLC | DELTA |

| Skrine se thetsoang | MCGS |

| Servo Motor | DELTA |

| Asynchronous Motor | CHEMEKE |

| Mofetoleli oa khafetsa | DELIXI |

| Transducer | OMDHON |

| Setene se futhumatsang | TS'ELISO |

| AC Contactor | CHNT |

| Relay ea Thermo | CHNT |

| Relay ea Mahareng | CHNT |

| Relay ea naha e tiileng | CHNT |

| Valve ea Solenoid | AirTAC |

| Phetoho ea Moea | CHNT |

| Air Cylinder | AirTAC |

| Valve e Laolang Khatello | AirTAC |

Ke Hobane'ng ha U Re Khetha - Melemo ea ho sebelisa lijana tsa PLA tse ka senyehang ka mor'a thibelo ea polasetiki

- GTMSMART tharollo ea sehlahisoa sa PLA ea sebaka se le seng

- PLA biodegradable setshelo sa lijo

- PLA-e leng thepa e ncha e se nang botsoalle le e senyehang e amoheloang ke lefatše

- Eco-friendly le biodegradable

- Anti-grease ha ho bonolo ho phunyeletsa

- E sebetsang

- Ho hanyetsa mocheso o matla

Mochini oa Thermoforming oa PLA oa Plastic Box Box, Re amohela ka tieo bareki ba kantle ho naha ho buisana le tšebelisano ea nako e telele.

Mochini oa lebokose la lijana tsa polasetiki tse maemong a holimo, mochini o lahloang oa ho etsa lijana, lisebelisoa tsa terei, mochini o etsang thermoforming, mochini o etsang lijana tsa polasetiki, mochini oa thermoforming, Re balekane ba hau ba tšepahalang mebarakeng ea machabeng e nang le lihlahisoa tsa boleng bo holimo. Melemo ea rona ke boiqapelo, ho tenyetseha le ho ts'epahala tse ahiloeng lilemong tse Leshome tse fetileng. Ho ba teng ha rona khafetsa ha lihlahisoa tsa boemo bo holimo hammoho le tšebeletso ea rona e ntle ea pele ho thekiso le ka mor'a thekiso ho netefatsa tlholisano e matla 'marakeng o ntseng o eketseha oa lefatše.

Re romelle molaetsa oa hau:

Lihlahisoa tse khothalelitsoeng

Tse ling +-

Mohlala: HEY01

Mohlala: HEY01PLC Pressure Thermoforming Machine e nang le Liteishene tse tharo HEY01

PLC Pressure Thermoforming Machine e nang le Liteishene tse Tharo tsa HEY01 Selelekela sa Sehlahisoa Mochini ona oa Thermoforming oa Khatello Haholo-holo bakeng sa tlhahiso ea lijana tsa polasetiki tse fapaneng (tray ea mahe, cont fruit... -

Mohlala: HEY02

Mohlala: HEY02Liteishene tse 'ne Mochini o Moholo oa PP oa Plastic Thermoforming HEY02

Selelekela sa Sehlahisoa Mechini e Mene e Meholo ea Thermoforming ea Plastiki Haholo-holo bakeng sa tlhahiso ea lijana tsa polasetiki tse fapaneng (terei ea mahe, sejana sa litholoana, setshelo sa lijo, lijana tsa liphutheloana, jj)... -

Mohlala: HEY03

Mohlala: HEY03Mochini o le mong oa Seteishene o Iketselitseng Thermoforming HEY03

Kenyelletso ea Sehlahisoa Mochini o le Mong oa Thermoforming Mochini o Iketselitseng Haholo bakeng sa tlhahiso ea lijana tsa polasetiki tse fapaneng (tray ea mahe, setshelo sa litholoana, setshelo sa lijo, lijana tsa liphutheloana, jj) ka ... -

Mohlala: HEY06

Mohlala: HEY06Liteishene tse Tharo Mochini o Etsang Khatello e Ntle HEY06

Sets'oants'o sa Mechini e Metle ea Ho Etsa Khatello e Ntle ea Liteishene HEY06 Mochini ona oa Thermoforming Haholo-holo bakeng sa tlhahiso ea lijana tsa polasetiki tse fapaneng (tray ea mahe, setshelo sa litholoana, setshelo sa sephutheloana... -

Mohlala: HEY12

Mohlala: HEY12Mochine o Felletseng oa Mohope oa Plastic oa Servo o Etsang Mochini oa HEY12

Mochini oa ho etsa linoelo tse felletseng tsa Servo Plastic Cup Mochini oa ho etsa linoelo ke oa ho etsa lijana tsa polasetiki tse fapaneng (likopi tsa jelly, linoelo, lijana tsa liphutheloana,... -

Mohlala: HEY11

Mohlala: HEY11Hydraulic Servo Plastic Cup Thermoforming Machine HEY11

Hydraulic Servo Plastic Cup Thermoforming Machine HEY11 Cup Thermoforming Machine kopo Mochini oohle oa Thermoforming Mohope oa Plastiki Haholo-holo bakeng sa tlhahiso ea lijana tsa polasetiki tse fapaneng (... -

Mohlala: HEY05

Mohlala: HEY05Mochini oa ho Etsa Mokelikeli oa Plastiki HEY05

Tlhaloso ea Mochini oa Vacuum Thermoforming Vacuum forming, eo hape e tsejoang e le thermoforming, vacuum pressure form kapa vacuum molding, ke ts'ebetso eo ho eona letlapa la polasetiki e futhumetseng le...